OUR PRINTING SERVICES

As part of Tealwood Group, the South Coast’s leading printing and engraving company, we offer a wide range of additional services to complement our large-format printing solutions. In addition, our factory is equipped to handle various other printing needs.

Screen Printing

From large industrial panels to smaller commercial items, we can handle it all on a range of screen printing benches, from 8′ x 4′ and beyond. The traditional screen printing process is incredibly versatile, allowing us to print on virtually any surface.

Custom-made Badges

Our custom-made badges offer a personalised touch for any event or brand. Available in various shapes, sizes, and finishes, we use high-quality materials to ensure each badge meets your exact specifications. Perfect for promotions or special occasions, they’re designed to stand out and last.

Rotary Printing

The printing of cylindrical items can present a whole new set of problems, particularly if multiple colours are involved however we have many years of tackling this type of work. Examples of rotary printing onto cylindrical items include of pens, bullet casings, buckets, helmets and mugs/jugs.

Engraving

We have been offering engraving services since 1966 including machine engraving (CNC & pantograph), laser engraving & cutting.

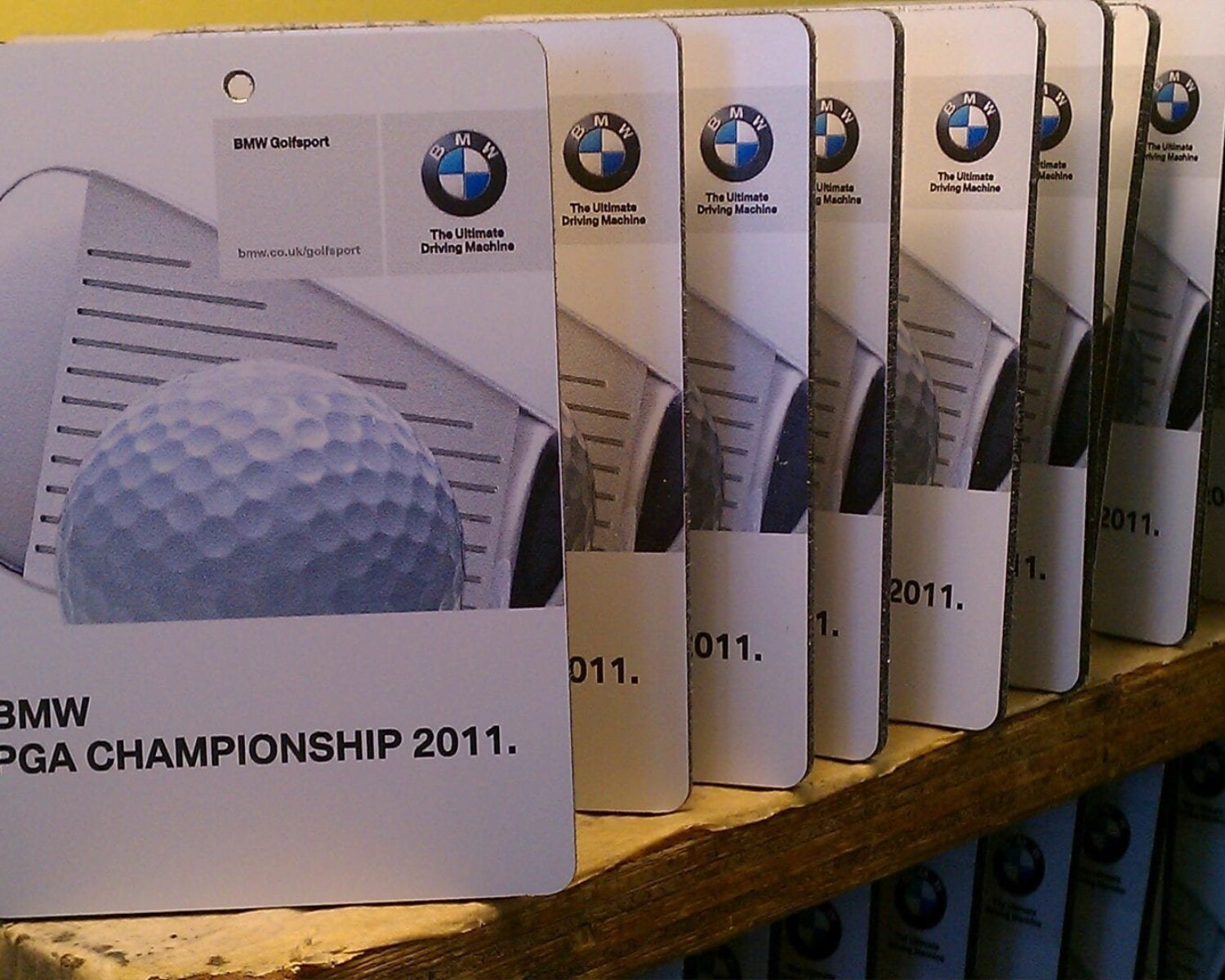

Pad Printing

Our Pad Printing department can cover almost anything, from everyday products to objects of a more specialised or technical nature, whether it be irregular, concave or convex shaped. Examples include pens, golf balls, injection moulded parts and keytops.

Vacuum Forming

We are able to print onto a plastic film which is then applied and wrapped onto a 3D product, in a process known as vacuum forming.

UV digital flat-bed digital printer

The diversity of our flat-bed digital printer enables us to print onto almost anything up to A3 in size and 150mm thickness. Custom digital printing examples include boxing gloves, coasters, clocks, book covers and badges.

Fabricating

Plastic fabrication from line bending

to vacuum forming

.

Additional Services

Laminating process

We have on-site laminating facilities to protect your finished products.

Adhesive backing to products

We laminate the printed materials with adhesive backing ready for you to apply.

Eyeletting machine

Our machine punches a hole and inserts metal rivets to reinforce the holes on flexible media such as banners.

Laser cutting and finishing service

We have in-house cutting technology for complex shapes and patterns. Services includes laser cutting out, contour cutting and kiss cutting.

Site visit

For large scale projects we can carry out on-site feasibility visits to manage your project.

Supply of materials

We don’t just print, we can source the products and materials for your project, whether it’s a bespoke one-off job or mass printing.

Installation Service

From the initial site survey to the final installation, find out more about our installation service.